Processes

- Step 1: Collection of Waste Rubber Tires

The first step is the collection of waste rubber tire that you want to recycle

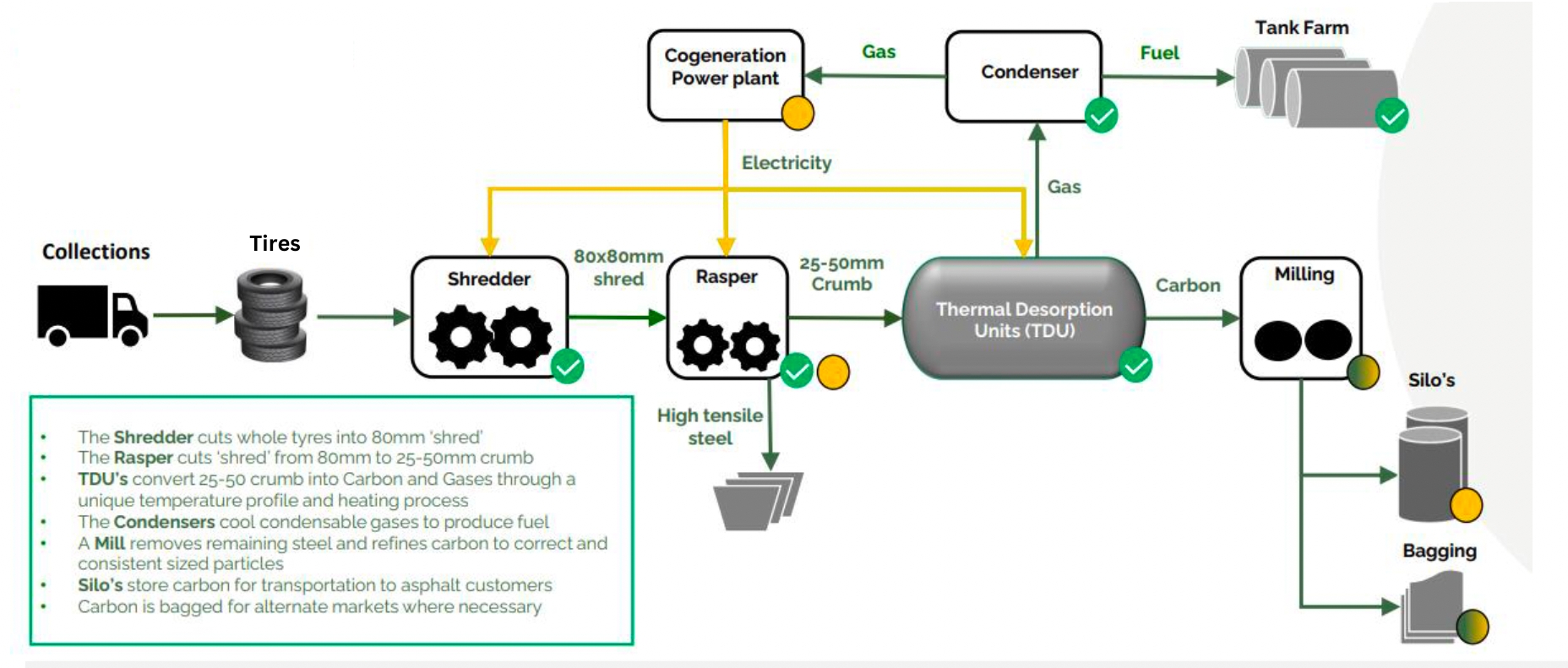

- Step 2: Shredding of Waste Rubber Tires

Next, the tires are cut into smaller pieces to facilitate handling and processing. Tire shredding can be performed using mechanical or cryogenic systems.

Mechanical Shredding:

This involves shredding scrap tires into smaller chips at ambient temperature. Depending on the intended use of the recycled rubber, the waste may be cut into progressively smaller pieces as the fiber is removed. The end product is known as ‘crumb rubber.

Cryogenic Shredding:

In this process, the temperature is lowered to between -80°C and -120°C. The shredded or whole tire is cooled until it becomes glass-hard and brittle, then crushed or ground to a fine size of 50-250 mm in specialized mills.

- Step 3: Sorting

Textile fibers and steel are removed from the shredded rubber using magnets, which extract the steel fibers from the rubber mix.

- Step 4: Screening

Following the separation of wires, the rubber undergoes screening to ensure no steel remains. This involves examining large volumes of rubber, sorting them by size, and eliminating any unwanted substances. Screening also includes reducing the sizes of larger rubber pieces.

- Step 5: Cleaning

The screened rubber is thoroughly cleaned using water and various cleaning agents to prepare the final product.

- Step 6: Packaging & Transportation

The cleaned rubber is then packaged and delivered to factories that use it as raw material for their products, such as manufacturers of rubber shoes and playground turfs.

Tyre to Shreds